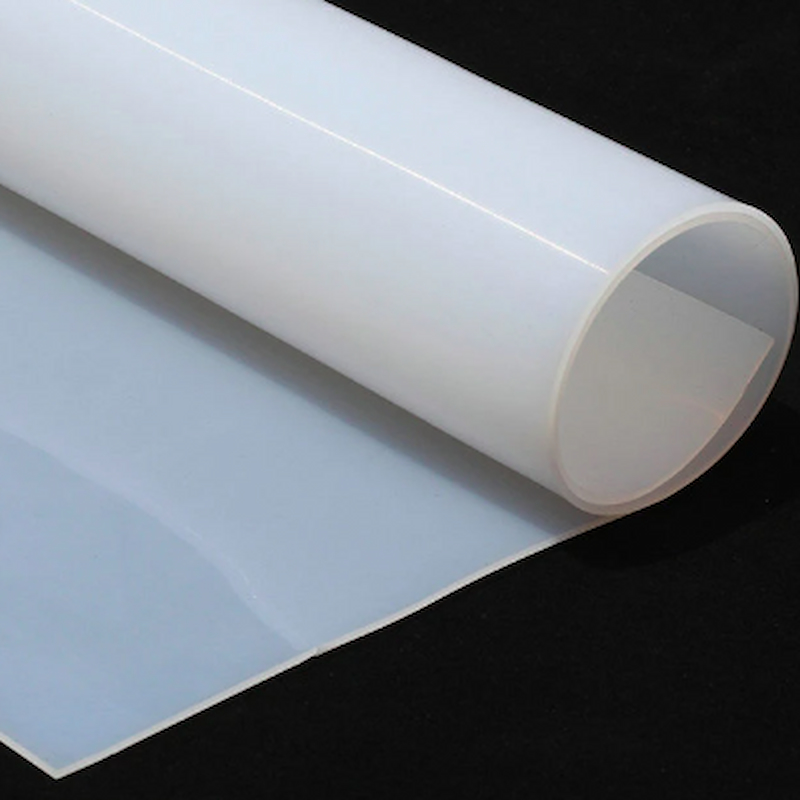

Placas de silicone industriais são um material versátil amplamente usado em várias aplicações devido às suas propriedades térmicas excepcionais e resistência a produtos químicos. Feitas de silicone de alta qualidade, essas placas oferecem excelente condutividade térmica, estabilidade térmica e isolamento elétrico. Elas são ideais para uso em dispositivos eletrônicos, componentes automotivos e equipamentos industriais onde o gerenciamento de temperatura é crucial. As placas de silicone também são conhecidas por sua durabilidade e flexibilidade, tornando-as adequadas para ambientes exigentes. Elas podem suportar altas temperaturas, variando de -60°C a +200°C, sem comprometer seu desempenho. Além disso, são resistentes à água, ácidos, bases e muitos outros produtos químicos, garantindo sua longevidade e confiabilidade. Na indústria eletrônica, placas de silicone são comumente usadas como dissipadores de calor, materiais de interface térmica e isolantes. Sua capacidade de transferir calor de forma eficiente e evitar superaquecimento melhora o desempenho e a vida útil de dispositivos eletrônicos. No setor automotivo, elas encontram aplicação em componentes de motor, sistemas de gerenciamento térmico de bateria e outras áreas onde o controle de temperatura é vital. Além disso, placas de silicone industriais são usadas na fabricação de painéis solares, pois fornecem excelente isolamento elétrico e podem suportar temperaturas extremas encontradas em ambientes externos. Sua resistência à radiação UV e ao envelhecimento garante estabilidade e desempenho de longo prazo. Concluindo, placas de silicone industriais são uma escolha de material confiável e eficiente para aplicações que exigem gerenciamento térmico e resistência química excepcionais. Sua durabilidade, flexibilidade e ampla faixa de temperatura as tornam uma solução ideal para várias indústrias, contribuindo para melhor desempenho e confiabilidade do produto.

VEJA MAIS

O QUE VOCÊ ESTÁ PROCURANDO?

Pesquisas populares

Rede IPv6 suportada

Rede IPv6 suportada